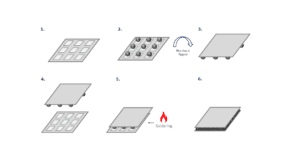

Fluxless TCB vs TCB

As interconnection pitches shrink below 10µm for advanced logic and memory applications, fluxless TCB solves the issues that standard TCB encounters with the flux.

Semiconductor fabs have high fixed costs and need to operate 24/7 to generate the necessary economies of scale. A higher chip yield means more healthy chips can be produced using the same number of wafers, which lowers production costs as foundries will spend less on raw materials and energy.

Customers typically pay for total wafer output, so a higher yield will also lower their expenses while improving satisfaction. Samsung knows well that when you are unable to deliver acceptable fabrication yields, customers will switch to competition. The firm has lost important customers in 2023 as its 3nm process was not providing the required yield. Furthermore, higher yields generate higher profit margins which fabs can use to reinvest into expansion, research & development or new equipment.

A chip must undergo more than 12 highly technical processes during manufacturing. Some of these processes, such as lithography, are extremely critical, and even a deviation of a few nanometers could render the chip defective.

Semiconductor yield can be improved in many ways.

Sometimes a simple change, such as switching to a higher-quality silicon provider, will improve yields. Other times it might require more sophisticated techniques. Engineers apply process control to achieve higher yields. This involves monitoring the semiconductor equipment, identifying deviations, and making appropriate adjustments. Process control also uses statistical methods for early detection and prevention of defects. Reducing process variability is also key, as variability can lead to a lack of consistency. Fab standardization is crucial to facilitate knowledge sharing between employees, improve efficiency and reduce testing and manufacturing costs.

As interconnection pitches shrink below 10µm for advanced logic and memory applications, fluxless TCB solves the issues that standard TCB encounters with the flux.

The front-end and back-end are highly interdependent. A constant feedback loop between front and back-end engineers is necessary to improve manufacturing yields.

Wire bonding is a cheap and reliable semiconductor packaging method- Flip-chip is an advancement, creating more dense interconnections and allowing 3D vertical stacking.

Fab yield refers to the percentage of working chips in a semiconductor wafer. If a fab can’t meet the requirements, customers will switch to another