Fluxless TCB vs TCB

As interconnection pitches shrink below 10µm for advanced logic and memory applications, fluxless TCB solves the issues that standard TCB encounters with the flux.

A generator governor is a device that controls the speed of a generator. It is like a brain that tells the generator how fast or slow it needs to spin in order to produce the right amount of electricity.

Imagine you have a toy car with a speed control knob. Turning the knob makes the car go faster or slower. The generator governor works in a similar way, but instead of controlling a toy car, it controls the speed of a generator.

The generator governor constantly monitors the speed at which the generator is spinning. If the generator starts to spin too fast, the governor slows it down. If it starts to spin too slow, the governor speeds it up. This helps to maintain a steady and stable output of electricity. The governor does this by adjusting the amount of fuel going into the generator’s engine. Just like a car needs gas to run, the generator needs fuel to produce electricity. By controlling the fuel flow, the governor can ensure that the generator produces the right amount of electricity even when the demand for power cha

The generator governor is an important part of a generator because it helps to keep the generator running at the right speed to meet the electricity needs of the people who are using it. It helps to ensure a steady and reliable supply of electricity, just like the way a traffic cop helps to keep the cars moving smoothly on the road.

The hydroelectric power plant in this case study is a crucial source of electricity for a region. It consists of a dam, a reservoir, and turbines connected to generators. The plant’s original generator governors, which control the speed and output of the generators, were outdated and unreliable. This caused inefficiencies, reduced power output, and increased maintenance costs.

Challenges:

Solution:

The power plant management decided to upgrade the generator governors to modern, computer-controlled systems to address the challenges and improve overall efficiency and reliability. The following steps were taken:

Results:

The upgrade of the generator governors at the hydroelectric power plant yielded several significant benefits:

In conclusion, the successful upgrade of the generator governors at the hydroelectric power plant not only improved operational efficiency but also enhanced safety and reduced maintenance costs. This case study highlights the importance of keeping control systems up-to-date in critical infrastructure to ensure reliable and efficient operation.

The main applications of a generator governor is in power plants. These facilities can range from large-scale thermal, hydroelectric, or nuclear plants to smaller diesel or gas turbine stations. Regardless of the power generation technology, maintaining a stable frequency is essential for the synchronized operation of the grid. The generator governor senses any deviation in frequency caused by changes in the load and adjusts the fuel or mechanical input to re-balance the system.

It is also utilized in backup power systems. These systems, commonly found in hospitals, data centers, or critical infrastructure, provide electricity during emergency situations or power outages. Generator governors ensure a smooth transition from the main power supply to the backup generator and maintain a stable frequency throughout the power restoration process.

Renewable energy sources also rely on generator governors for optimal performance. Wind farms, for example, use wind turbines equipped with governors to regulate the generator speed and adapt to varying wind conditions. This allows for efficient energy capture while maintaining a stable grid frequency.

The transportation sector also benefits from generator governors, particularly in locomotives and ships. Diesel-powered trains and ships employ governors to control the engine speed and power output, ensuring reliable performance and fuel efficiency during operation.

In addition to these primary applications, generator governors find use in various industrial processes that require a stable power supply. Manufacturing facilities, chemical plants, mining operations, and oil refineries often integrate generator governors to maintain production continuity and prevent costly downtime due to power fluctuations.

The first Governors for steam engines were introduced in the late 17th century, and they played a crucial role in regulating the speed and power output of early steam engines. However, it wasn’t until the 19th century, with the advent of electrical power generation, that governors specifically designed for generators came into use.

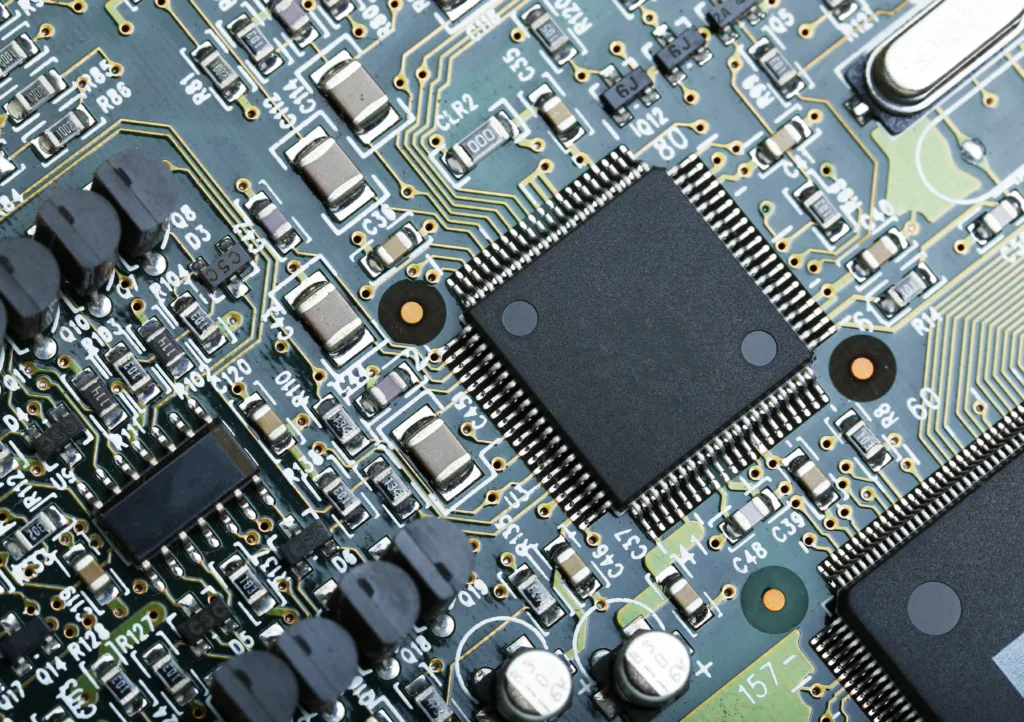

In the early days of electricity, generators were prime-movers driven by steam engines or water turbines. These generators were typically equipped with centrifugal governors, which controlled the speed of the prime-mover to maintain a constant frequency and voltage output. These mechanical governors used flyweights that responded to changes in generator speed and adjusted steam flow or water flow to maintain a stable power output.

As the power grid expanded and demand for electricity increased, there was a need for more advanced and precise governor systems. In the early 20th century, mechanical governors were gradually replaced by more sophisticated hydraulic and electro-hydraulic governor systems. These systems utilized hydraulic or oil pressure to control the speed and power output of the generator.

With advancements in digital technology, electronic governors began to replace hydraulic governors in the late 20th century. Electronic governors utilize sensors, control algorithms, and electronic circuits to monitor and regulate generator speed and power output. These systems offer greater accuracy, faster response times, and more flexible control options.

In recent years, there has been a shift towards more integrated and automated generator control systems. These systems incorporate not only the governor function but also other aspects of generator control such as voltage regulation, protection, and synchronization. They often include advanced features such as remote monitoring and control, data logging, and diagnostics.

As interconnection pitches shrink below 10µm for advanced logic and memory applications, fluxless TCB solves the issues that standard TCB encounters with the flux.

The metal pitch refers to the distance between the centers of two adjacent metal interconnect lines on an integrated circuit (IC). Since transistors evolved into 3D strucrures, this measurement has lost significance.

The front-end and back-end are highly interdependent. A constant feedback loop between front and back-end engineers is necessary to improve manufacturing yields.

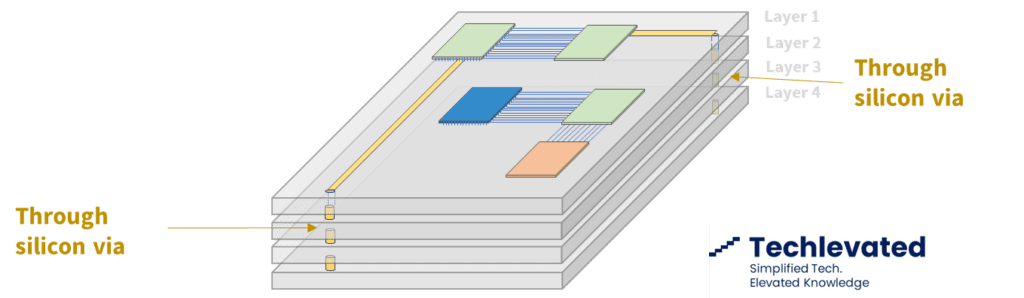

Built directly into the silicon, through silicon vias (TSV) facilitate 3D IC integration and allow for more compact packaging. They have become the default solution to interconnect different chip layers or to stack chips vertically.

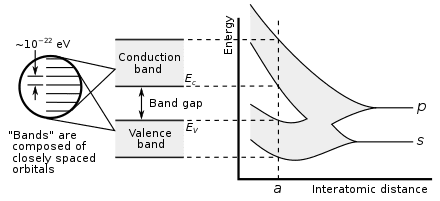

Silicon carbide (SiC) is used in electric vehicles due to its wide bandgap and great thermal conductivity. Gallium nitride (GaN) shares many characteristics with SiC while also minimizing RF noise.

GPU vs CPU is a parallelization vs complexity dilemma. While GPUs can manage very large parallel calculations, they struggle with linear, more heterogeneous tasks, where CPUs excel.