Illustrative Case Study: ZnO in Thin-Film Transistors (TFTs)

In this case study, researchers aimed to investigate the feasibility of using zinc oxide as the semiconductor material in thin-film-transistors, TFTs, for display applications. They wanted to determine if ZnO could offer advantages over traditional silicon-based TFTs, such as improved performance, cost-effectiveness, and ease of manufacturing.

Conclusion First:

The case study demonstrated that zinc oxide has the potential to be a viable semiconductor material for thin-film transistors in display applications. While challenges exist, ongoing research aims to overcome them and further optimize the performance of ZnO-based TFTs, potentially leading to more efficient and cost-effective electronic devices in the future.

Key Steps:

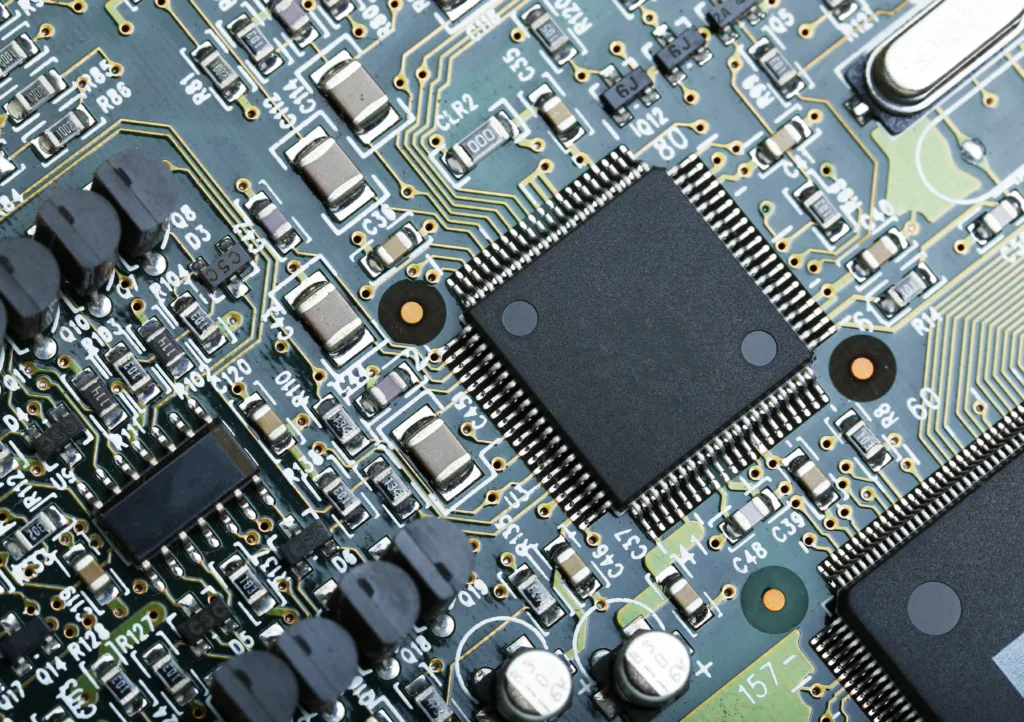

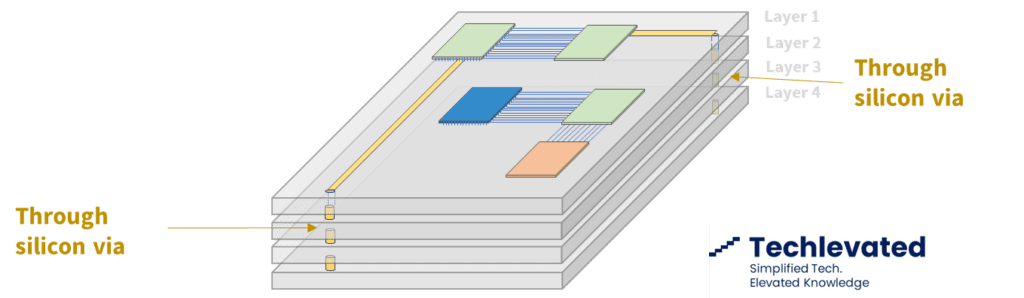

Material Deposition: The researchers deposited a thin layer of zinc oxide onto a substrate, forming the semiconductor layer of the Tft. They used a technique like sputtering or chemical vapor deposition to create a uniform layer.

Device Fabrication: The semiconductor layer was patterned to create the necessary transistor structure. This included defining the source, drain, gate, and channel regions.

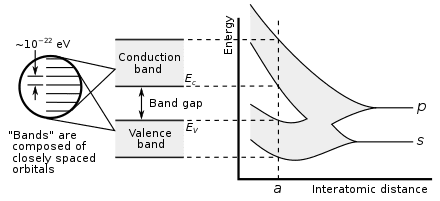

Characterization: The electrical properties of the ZnO-based TFT were extensively characterized. This involved measuring parameters such as mobility (how quickly charge carriers move through the material), on-off ratio (the difference in conductivity between the on and off states), and threshold voltage (the voltage at which the transistor turns on).

Comparison: The performance of the ZnO-based TFT was compared to traditional silicon-based TFTs. Researchers looked at factors like switching speed, power consumption, and reliability.

Findings:

The researchers found that zinc oxide had several favorable properties for TFTs:

High Mobility: ZnO exhibited good charge carrier mobility, enabling fast switching speeds in the transistors.

Transparency: ZnO is transparent, which is beneficial for applications like transparent displays and touchscreens.

Flexibility: ZnO-based TFTs could potentially be used in flexible and bendable electronics due to the material’s mechanical properties.

Cost-Effectiveness: ZnO can be deposited using relatively simple and cost-effective techniques, which could lead to more affordable manufacturing processes.

Challenges:

However, the study also highlighted some challenges:

Stability: ZnO-based devices can be sensitive to environmental conditions, affecting their long-term stability.

Interface Quality: The interface between ZnO and other layers in the TFT structure can impact performance. Achieving a high-quality interface is crucial.

Interface Quality: The interface between ZnO and other layers in the TFT structure can impact performance. Achieving a high-quality interface is crucial.

Conclusion:

The case study demonstrated that zinc oxide has the potential to be a viable semiconductor material for thin-film transistors in display applications. While challenges exist, ongoing research aims to overcome them and further optimize the performance of ZnO-based TFTs, potentially leading to more efficient and cost-effective electronic devices in the future.